Engineering

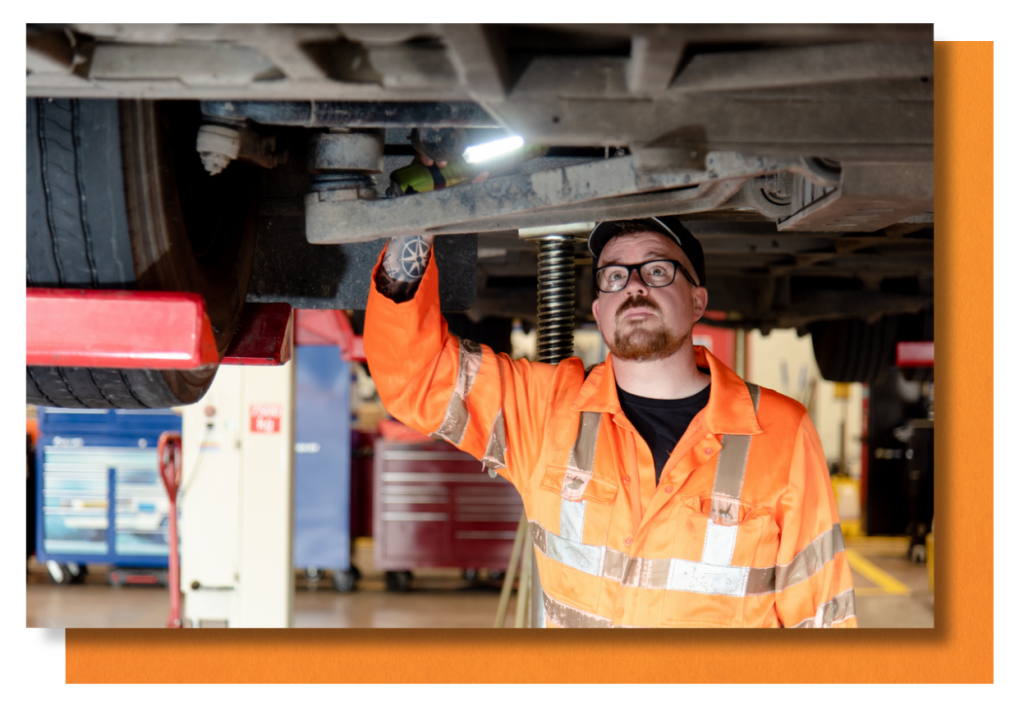

Our fleet is maintained in-house in a dedicated workshop with a workforce of over 16 technicians.

Shiftwork to support the ‘around the clock’ SPS operation sees the workshop operate 24 hours a day seven days a week. Our state-of-the-art 10 bay vehicle maintenance facility is fully equipped with modern engineering equipment. The engineering team also provide roadside assistance for the fleet.

Due to the nature of our operation, work patterns change frequently which affects PVR with an ever-changing vehicle demand. Our engineering team ensures a consistent PVR output and service delivery and are pro-active and adept at preempting and circumventing daily supply chain issues to minimise service and PVR implications, ensuring vehicles are returned to service and unnecessary delays and service disruption are avoided.

Innovation within our Engineering Department:

Ben Scott-Davies - Workshop Manager

To help reduce the negative impact of nearside mirror collisions, Ben took the initiative to introduce an engineering solution. Initially, taking the time to personally review the hedgerows and furniture along a hazardous road, to better understand the current risks and then explored options for alternative styles of mirrors for single and double decker buses.

Ben sourced new ‘indestructible’ plastic bus mirrors which would reduce the likelihood of damage in the event of a hedgerow collision. Then, to help reduce the likelihood of a collision at all, these mirrors were fitted upside down – reducing the amount of overhang on the sides of the vehicle.

This was done in such a way so as not to negatively impact visibility for drivers. This innovation has demonstrably contributed to a reduction in nearside mirror damage on our buses, reduced cost and improved vehicle uptime, and positively impacts SPS’s reputation with our client and passengers. A great demonstration of initiative being taken to reduce costs, improve safety and enhance service.

Our Engineering Team